Contact us for a free local system survey

doug_robertson@asrsystems.com

Cell: 847-508-0538

Serving GA, FL, NC, SC & VA

Contact us for a free local system survey

doug_robertson@asrsystems.com

Cell: 847-508-0538

TRIDENT HORIZONTAL CAROUSELS

Old-School Each Pick Efficiency Meets Modern Automation

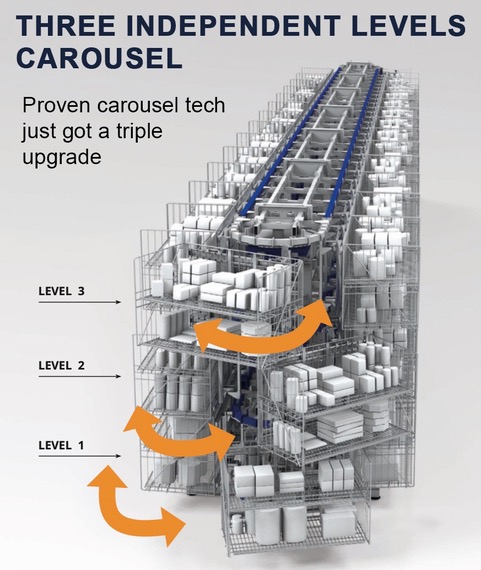

- Proven carousel tech just got a triple upgrade

- Three independent levels enable simultaneous pick & put-away for broken case picks

- Magic Warehouse™ provides smart decision making for all other logistics processes

The next generation of horizontal carousels: METALPROGETTI TRIDENT brings automation to a new dimension with three fully independent operating levels, instantly

tripling performance. While one level serves the operator, the other two keep moving, enabling simultaneous picking and refilling with zero downtime.

This continuous flow delivers measurable results: orders up to 60% faster and 50% less floor space required, with operations managed in a precise and reliable way.

Already integrated with Magic Warehouse™ software and interfacing seamlessly with any ERP or WMS, TRIDENT provides real-time control of batching, slotting,

replenishment, and inventory.

With TRIDENT, it’s the product that moves – not the operator. The outcome: greater ergonomics, enhanced safety, and maximum productivity.

Call us at 847-508-0538 for more details

Zero-Downtime Picking & Filling

Trident is truly revolutionary : it is the only

horizontal revolving warehousing system on

several independent levels. At each level,

the baskets full of items rotate autonomously,

choosing the direction of rotation in order to reach

the operator who needs to retrieve an item from

that basket, the faster way.

Trident is quick: the rotation speed of the baskets,

set depending on the items to be conveyed, varies

from 18 to 30 meters/minute (59 to 98 feet per

minute).

Trident is efficient: it consists of several levels that

operate independently from one another and

of baskets that can contain up to 12 item types

(6 for each of the 2 shelves in the basket), which

means the same item type can be stored in

different baskets and on different levels, thus

significantly reducing the time necessary to

assemble orders.

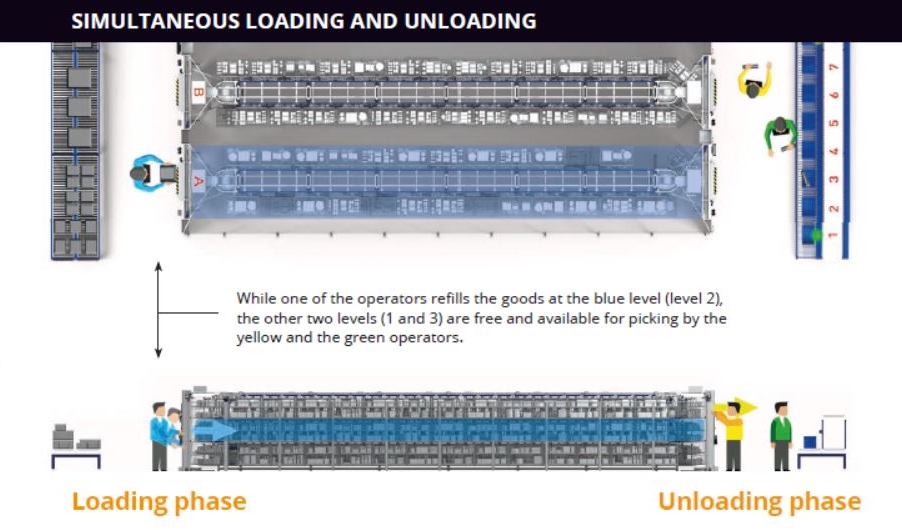

Another one of Trident’s winning features is

the possibility of refilling and picking products

simultaneously. If refilling is being carried out on one of

the levels, the other levels are free and available

for picking, as shown below.

Magic Warehouse™ Integration

The Trident PLC can be configured to communicate with our Magic Warehouse™ warehouse management

system.

This way, your business's order management

system will control the whole of Trident and

its operations.

The team at AS/R Systems will help you set up and customize all the hardware and software configuration steps necessary for seamless warehouse operations.

Advantages of the Trident Horizontal Carousel

- Simple & Reliable Operation - Trident means much more hardware than software, based on precision mechanics. Its operation is simple and reliable and requires very few checks, and those can be carried out by a general technician.

- Downtime is Minimized - With Trident, even if one of the levels breaks down, this doesn’t stop operation: each level is independent and the same item type can be stored on different levels. In the case of the breakdown or stoppage of one of the levels, the others keep working as normal. And even in the unlikely event of a total failure, 100% of the goods can be reached at eye level, as the operator can safely access them by using the side doors.

- Simple & Inexpensive Maintenance - Everything is easily accessible on Trident, and all checks can be performed by our technicians.

- Faster ROI - By using the Trident system, thanks to its high productivity, the return on investment is possible in a much shorter time than with other automatic warehousing systems.